TA_Amir Alavi_0055

“No batteries, no antennas, no electronics in vivo—no worries!” said Alavi, who also directs the Intelligent Structures and Architected Materials Research and Testing (ISMART) Lab. “By blending metamaterial design with nano-energy harvesting, we create fully battery-free, electronics-free implants that power themselves through contact electrification. They adapt to each patient and wirelessly transmit signals like a mini router inside the body.”

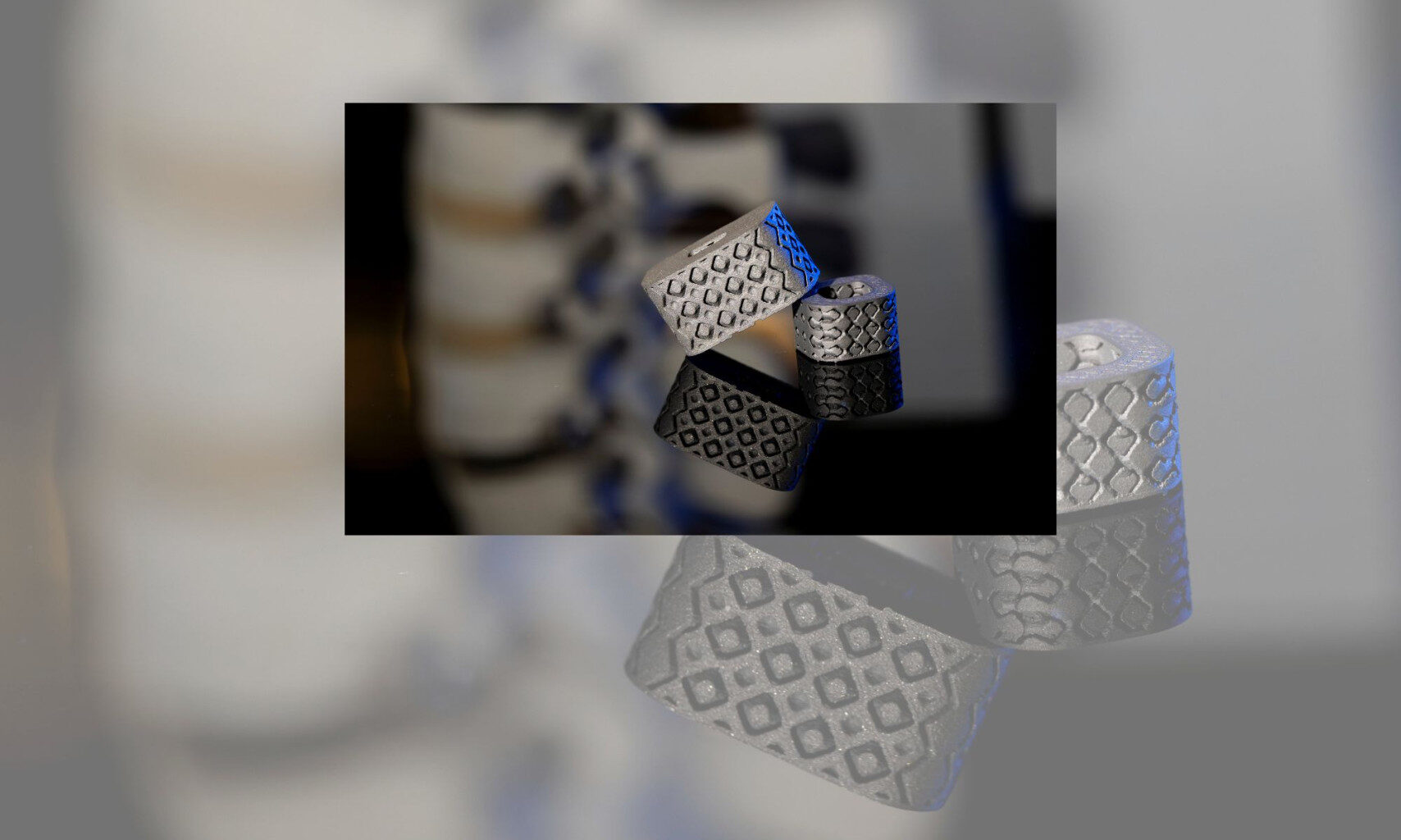

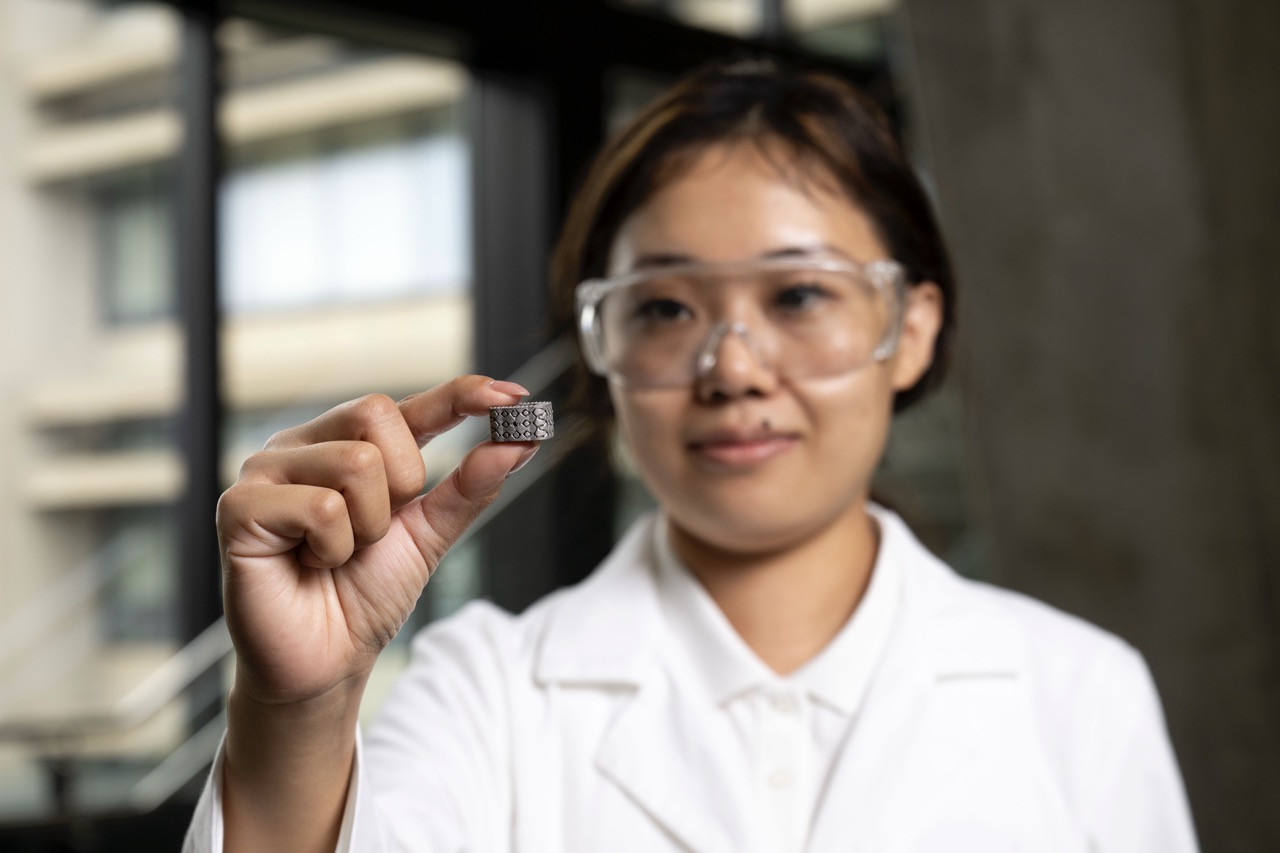

Using new, human-developed composites known as metamaterials, Alavi’s team has created structures consisting of different sized unit cells. By interweaving conductive and non-conductive materials, they can optimize these structures to harvest energy and transmit signals when pressure is applied to them.

From bridges to the back

In 2023, Alavi and Agarwal began a seemingly unlikely collaboration that integrated this technology in medical implants. The promise of their research is outlined in the Materials Today article “Wireless electronic-free mechanical metamaterial implants.”

“We’re creating cages for spinal fusion surgery that, like human cells, have a natural, built-in intelligence,” said Alavi.

These cages are set between two vertebrae and provide stability while also monitoring the healing process.

“If the spine is healing, the bone starts carrying more of the load and the implant’s self-generated signal naturally drops,” Alavi noted. “Right after surgery, the signal is stronger because the vertebral endplates press harder on the cage, so it generates more energy.”

The signals are received through an electrode on the patient’s back and transmitted to the cloud, where the signals can be interpreted in real time, allowing for medical intervention before more serious damage occurs.

‘;