Researchers from the Lanzhou Institute of Chemical Physics in China have reportedly developed a new ceramic that can be twisted, frozen, torched, and crushed without shattering. This new material could have important applications in various industries, including space flight.

Ceramics are excellent materials for handling heat, but tend to be fragile by their very nature. They don’t melt, burn, or soften easily, making them ideal for applications in engines, spacecraft, and hypersonic vehicles.

However, they are brittle, so bending or shocking them tends to make them shatter or crack. Heat them too long, and their internal structure coarsens, ruining performance.

One potential compromise is something called an aerogel, but this is not a silver bullet. Aerogels are better than ceramics at being a heat insulator because they are composed mainly of air.

However, they tend to be more fragile than traditional ceramic materials. In an ideal world, engineers would love to be able to have a ceramic that behaves mechanically like a sponge but thermally like a furnace brick.

Bendy ceramics are now a thing

To this end, the Lanzhou team set out to develop a ceramic aerogel that does just that. Through trial and error, they were able to develop an aerogel that can be squashed almost flat (98% compression). This material can also spring back like rubber when compressed.

The material is also stable under a wide range of temperatures, from liquid-nitrogen cold (32 °F/−196 °C) to red-hot (2,732°F/1,500 °C). It also insulates better than most high-temperature ceramics.

Traditional ceramics are brittle due to their atomic structure. They rely on strong, directional ionic/covalent bonds, which makes them great for heat resistance but terrible for flexibility. Once a crack starts, it races through the material.

At higher temperatures, atoms tend to migrate, and crystals grow inside their structure too. To overcome this, the team developed a new “high entropy” trick.

Instead of using one main metal oxide, they use five different metal atoms randomly mixed on the same crystal lattice. This forms a kind of atomic “chaos” that prevents heat from propagating easily through the aerogel.

This also means the material can’t readily “relax” when at high temperatures. They also found that the new ceramic aerogel is very elastic, something that shouldn’t be possible.

Important applications in industry

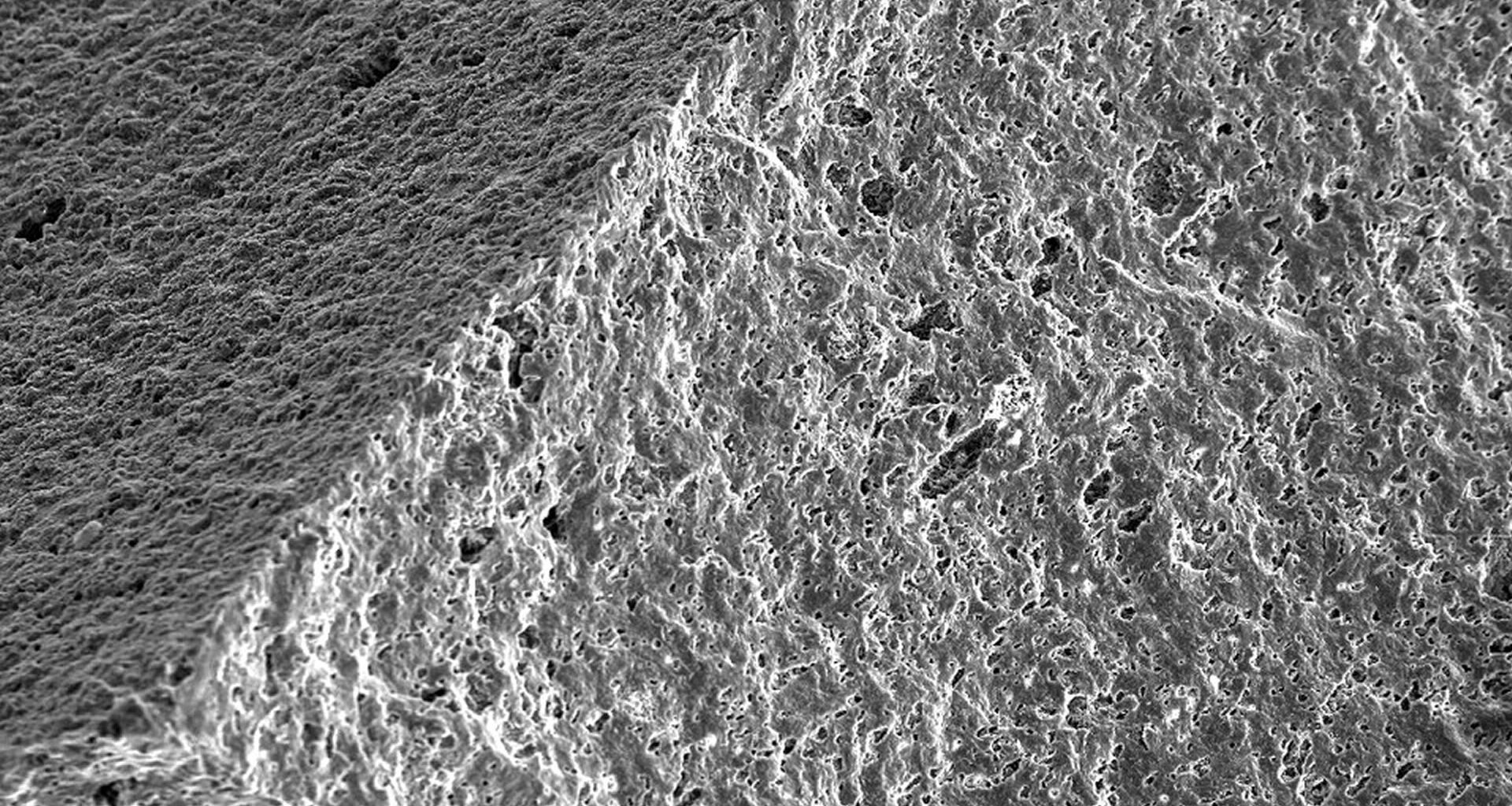

This is because the microstructure of the aerogel is something akin to a nanofiber network comprised of fibres around 250 nanometers thick. These are effectively woven into a 3D spring-like scaffold with large empty spaces between them.

This structure means the aerogel can be compressed readily as the fibers bend, buckle, and slide over one another. This also spreads the stress out over the material, reducing the chance of catastrophic failure of its structural integrity.

According to the team, this new material can have important applications in things like hypersonic vehicle skins. It could also be useful as insulation in things like turbines, as it doesn’t readily crack.

It could also be used for spacecraft heat shields, seals, and gaskets in extreme environments. This aerogel would also be useful for aerospace components that must survive vibration and heat.

You can view the study for yourself in the journal Advanced Science.