Here at Core77 we love to showcase student work. Troll readers love it too, because they get to insult kids. ID students among you, don’t listen to them. Design school is your time to explore, to experiment fearlessly. So build up your resilience now, and it will stand you in good stead when you eventually enter the workforce. (And remember that designers who take potshots at students probably aren’t very good designers.)

Here’s some good and great ID student work we saw this year:

By Teo Primo Frizzarin, an Industrial Design student at ECAL. It aims to consider the ergonomics of those working on a canvas rather than a desk.

It took “five months of struggle,” but Pratt ID student Dashiell Schaeffer successfully achieved his material usage goal.

By Aleš Urbancík, an Industrial Design student at Tomas Bata University in Zlín, Czech Republic. Urbancík is rethinking the way clothes are typically hung on a hanger, and finds this method, for which he developed a mechanism, more desirable.

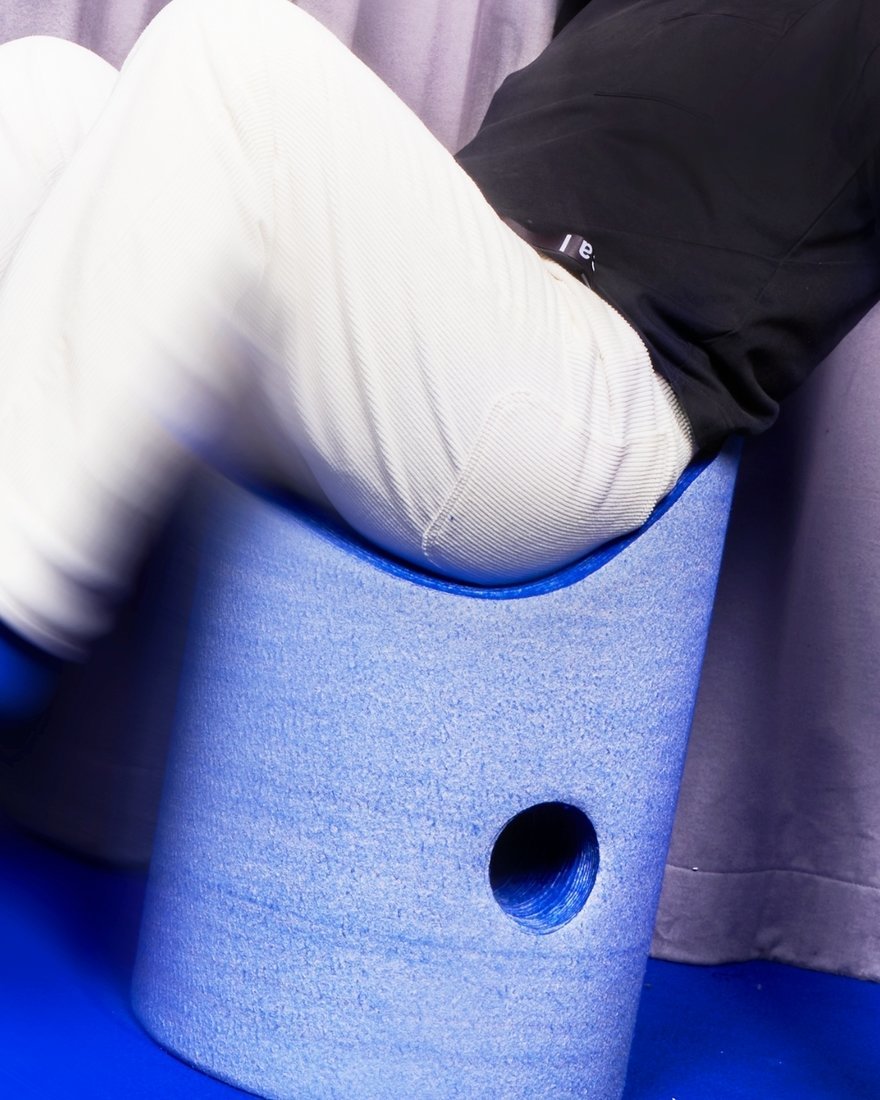

Auburn University partnered with KYRA, a medical equipment manufacturer, to task a team of both Industrial Design and Mechanical Engineering students with designing a surgical device.

By Weil, an Industrial Design student at ECAL. Weil sought to repurpose cast-off material as functional furniture.

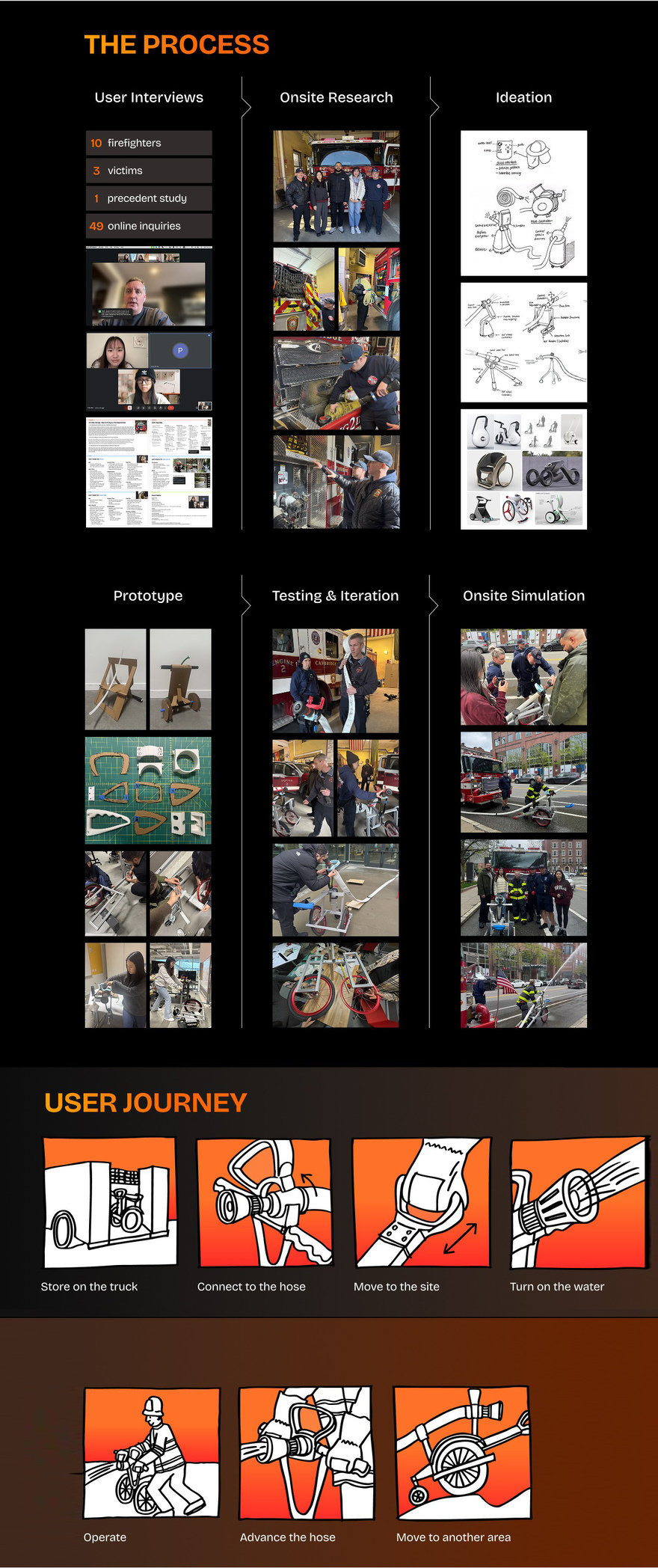

This Toos concept is by Industrial Design students Jeoung Rae Kim, Shua Bong and Seunghee Lee, of South Korea’s Hyupsung University. Collectively they call themselves Comma.

This CINTRE project is by Baptiste Marx, done when he was pursuing his Masters of Industrial Design at France’s ENSCI. Marx’s pre-ID degree was in “composite materials project management,” and both disciplines informed his approach to designing emergency housing.

This project is by Ziyan Huang, an Industrial Design Masters candidate at Germany’s Magdeburg-Stendal University of Applied Sciences. Huang’s Cursor Measurement Tool is a proposal for project sponsor Festool. The tool is intended to make it easier for tradespeople to transfer dimensions from blueprints onto the real-world spaces they’re building or installing within.

This isn’t an ID student project, but may as well be. It came out of a Design Engineering class at Harvard, and was executed by students Adrian Kombe, Meihan Liu and Sirinda Limsong. Tasked with using water to solve a problem, they replaced a $275,000 robot with a $750 solution.

This project was done by Denise Merlette, as her diploma project in Industrial Design at ECAL. Merlette seeks to turn what is considered by most furniture designers to be a useless part of the tree, the bark, into a useful resource.

This excellent Avants project is by Industrial Design student Juliette Masson. Done as her diploma project at ECAL, the project expores the use of more environmentally-friendly materials for technical clothing.

We’ve seen so many blue-sky ID school assignments that this one, which focuses on practicality, is refreshing. It’s from the “Basic Knowledge of Product Development” class at Germany’s Magdeburg-Stendal University of Applied Sciences, run by professor Mathias Bertram. Three student projects were featured.

This Quilted Furniture project is by Sapna Tayal, an Industrial Design student at Carnegie-Mellon University. I’d give her an “A;” Tayal has imaginatively harnessed production technology, collaborated with non-ID-department bodies and produced a highly professional level of documentation.

Tayal’s central question was: “How can we harness the unique capabilities of the overlooked CNC sewing machine, traditionally only used to make soft blankets, and expand its fabrication possibilities?” To get to the answer, she worked with researchers from CMU’s Human Computer Interaction Institute (HCII) and Robotics Institute (RI). Tayal created four objects overall.

This Hideaway shovel is by Wilhelm Berbig, done as an Industrial Design student at the Universität für angewandte Kunst Wien (University of Applied Arts Vienna).

In Austria, there are signposted hiking trails where you can bivouac in small abandoned sheds. Savvy hikers on multi-day treks bring their own toilet paper, but these sheds have no bathrooms. Berbig proposes stocking them with this shovel, in order that hikers can relieve themselves while leaving no trace.

This re-thinking of central heating systems is by Moritz Walter, done while pursuing his Master of Industrial Design degree at the Weissensee Kunsthochschule Berlin. Rather than relying on central boilers and radiators, Moritz took a cue from space heaters—minus the metal fins. Instead, Walter did testing with electrically-heated fabric, then experimented with a variety of elegant forms to support the fabric.

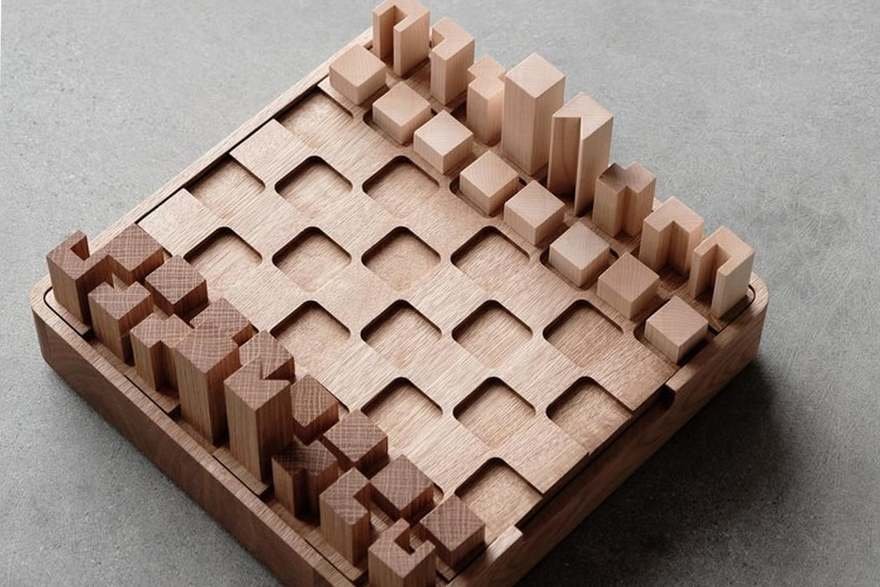

I think a good Industrial Design student assignment, particularly for sophomores, would be: Design and make a set of minimalist chess pieces–no digital fabrication nor individual sculpting/carving (unless making the pattern for a mold) allowed. This would cover a lot of skills that industrial designers need to develop.

Lastly, not ID students, but Architecture students. I think we can all remember in-studio disasters, and it’s good to see the students pushing through it.