Researchers from Henan University in China have reportedly developed a new type of ceramic fiber that can make piezoelectric nanogenerators (PENGs) much more powerful.

According to reports, the new development can triple the output of nanogenerators and enable accurate, self-powered monitoring of power grids.

For reference, piezoelectric materials generate electricity when they are pressed, stretched, or vibrated. PENGs use this effect to harvest tiny amounts of energy from mechanical movements, things like vibrations in a power line, human motion, or machinery.

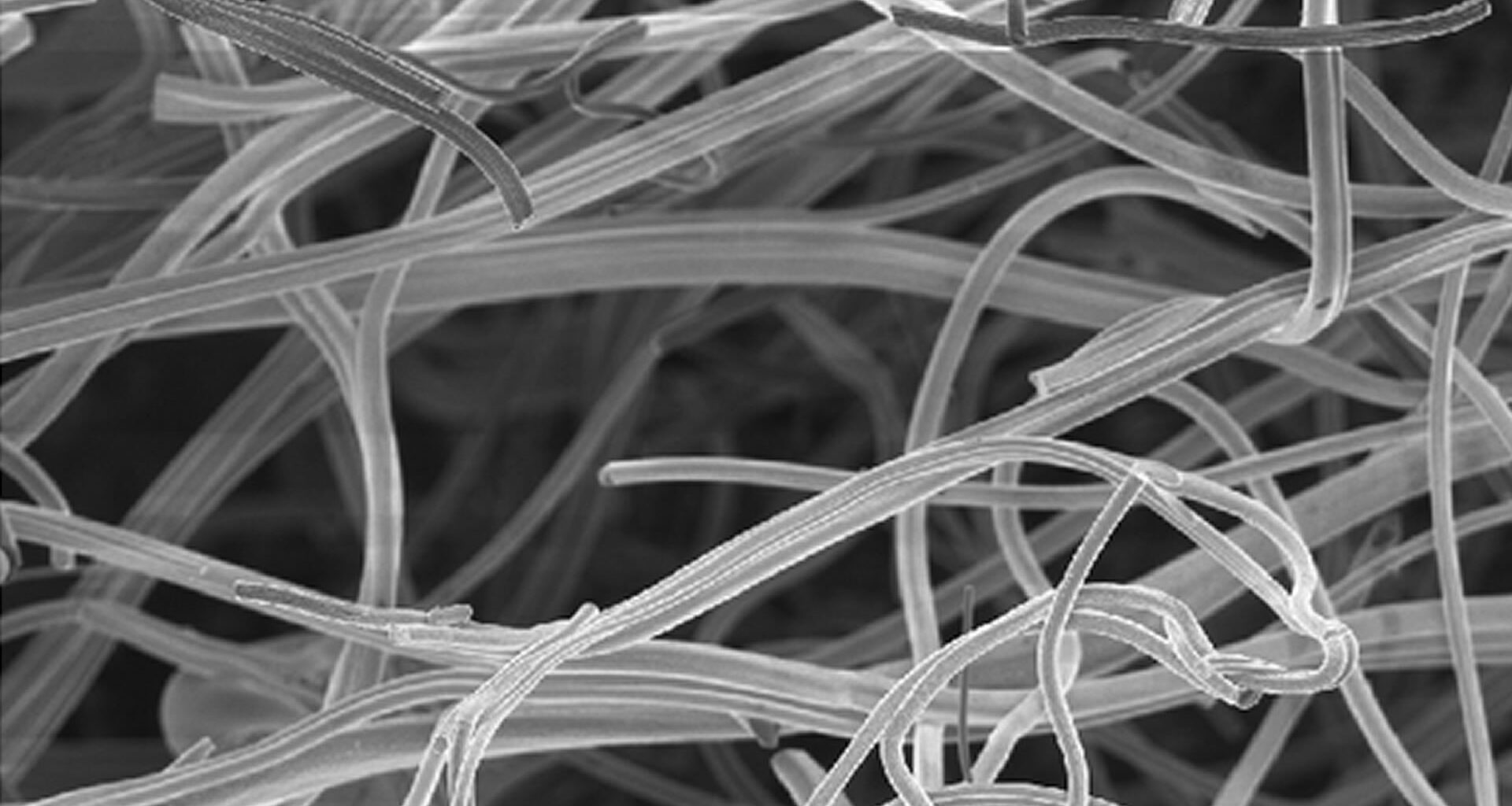

The team created branch-like ceramic fibers by coating a ceramic (BCZT or barium–calcium–zirconium–titanate) with silver nanoparticles. These fibers form a heterostructure (mixed structure with different materials) that improves how charges are separated and transported.

It is like giving the fiber extra pathways for electricity to flow and better “charge storage” ability. This new material is significant because it enhances the nanogenerator’s performance in two primary ways.

Brand new ceramic fibers

The first is better polarization efficiency as charges inside the material line up more strongly, so more electricity is generated. The second is more efficient charge transport.

When pressed, “Schottky barriers” (energy boundaries between silver and ceramic) help direct charges in the right way instead of scattering. According to the team’s paper on the subject, with this fiber mixed into a plastic (PVDF), the nanogenerator produced 96.4 volts and 15.52 microamps.

To put that into perspective, that’s around 3–6 times more output than without the special fibers.

The team built a prototype system to test the material and monitor power transmission lines.

They found that the nanogenerator harvested vibration energy from the lines themselves (so no batteries). If combined with circuits, wireless communications, and machine learning, it could detect whether a vibration-damping device was working normally, if it started to fail, or if it broke.

According to the team, this could have an accuracy of up to 96%. This demonstrates its potential for use in self-powered smart sensors on the power grid, enabling faster, cheaper, and safer maintenance.

Interesting potential for self-powered grid sensors

It is important to note that this is still very much early-stage research. The team needs to overcome some issues to make it useful in the real world.

For example, they need to push the output even higher and integrate it seamlessly with electronics. They also need to make it truly self-powered with no external backup and prove it works under messy real-world grid conditions.

“This excellent electrical output performance is crucial for efficient integration with energy management circuits and signal recognition systems in sensing applications,” said Professor Haowei Lu, a materials scientist at Henan University’s School of Physics and Electronics.

Looking at the bigger picture, this is a step toward developing battery-free, self-powered sensors for critical infrastructure, such as power grids. If it scales, it means smart monitoring systems that don’t need maintenance crews to constantly replace batteries, which would be a big win for reliability and cost.

The study was published in Journal of Advanced Ceramics.